Solving common pain points in order fulfillment

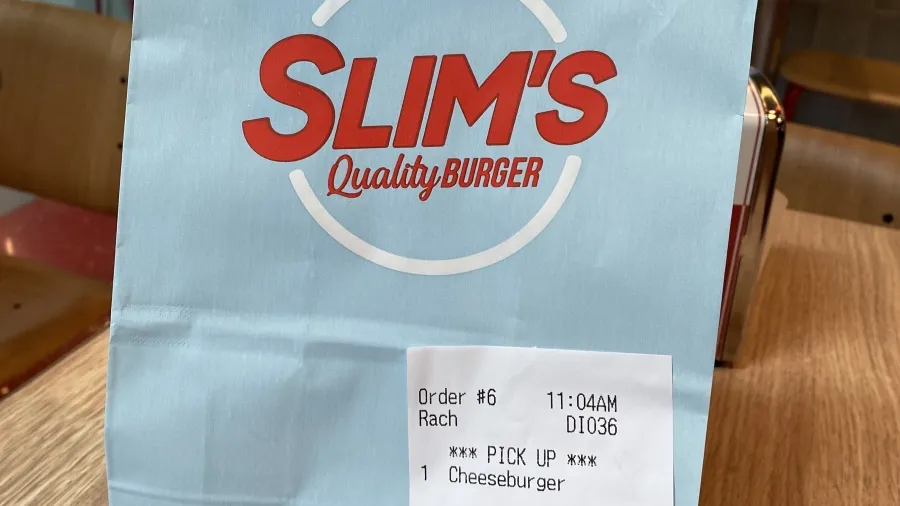

Something as simple as a label can help QSRs improve operations and customer experience.

Quick service restaurants (QSRs) are always looking for ways to improve their fulfillment processes and speed up service. Some QSRs have turned to technology to help them streamline their operations and meet customer expectations.

Technology has helped QSRs in a number of ways, from automating order taking to improving accuracy in order fulfillment. In addition to technology, some QSRs have also implemented other changes to their fulfillment processes, such as simplifying their menus and offering more customization options. These changes have helped QSRs improve their efficiency and provide a better experience for their customers.

In this article, we take a closer look at some of the pain points in QSR fulfillment processes and how some operators are using technology and other methods to overcome them.

Common pain points in order fulfillment

-

Accuracy

One of the biggest pain points for QSRs is accuracy in order fulfillment. In a fast-paced environment, it can be easy for mistakes to be made. This can lead to unhappy customers and lost business.

To help combat this issue, some QSRs have turned to technology, such as order management systems (OMS). OMSs can help QSRs keep track of orders and ensure that they are fulfilled correctly. Additionally, some QSRs have implemented barcode systems to help them keep track of orders and ensure accuracy.

Another way that QSRs are improving accuracy in order fulfillment is by simplifying their menus. By offering fewer menu items, QSRs can reduce the chances of errors being made. Additionally, some QSRs are offering more customization options to their customers. This allows customers to get the exact order they want, which can help reduce mistakes.

-

Speed of service

Another pain point for QSRs is the speed of service. In a fast-food world, customers expect their food to be served quickly and efficiently. If QSRs do not meet these expectations, they risk losing business.

To help improve the speed of service, some QSRs have turned to technology, such as point-of-sale (POS) systems. POS systems can help QSRs take orders quickly and efficiently. Additionally, some QSRs have implemented order-tracking systems. These systems can help QSRs keep track of orders and ensure that they are being fulfilled in a timely manner.

-

Lack of communication

Another issue that QSRs face is a lack of communication between the front and back of the house. This can lead to errors in orders and a lack of coordination. To help improve communication, some QSRs have implemented systems that allow the front and back of the house to communicate with each other. Additionally, some QSRs have put in place systems that allow customers to track their orders. This can help improve communication and coordination between the front and back of the house.

The importance of labels

But what if there was a way to make the order fulfilment process even more efficient? What if there was a way to improve accuracy and speed of service, while also reducing the chances of errors? And what if this product was as simple as a label?

Introducing StickyPOS, the patented, linerless direct thermal label specifically designed for the quick service restaurant (QSR) industry. StickyPOS is a labelling system that helps QSRs tag the wrapper, cup, box or bag of each product efficiently. This allows QSRs to track the product through the process from food preparation through to delivery.

StickyPOS has been proven to reduce order error rates by over 50%. Additionally, StickyPOS can help QSRs improve the speed of service. This is because the labels can be applied quickly and easily. And, because each product is labelled, QSRs can track orders more easily and ensure that they are fulfilled in a timely manner.

"StickyPOS works with any type of POS system, so it's very easy to implement," says Michael Sfetkidis, Managing Director, StickyPOS. "It's also very affordable, so it's a great solution for any QSR that is looking to improve their order accuracy and speed of service with a simple and cost-effective solution."

Furthermore, the StickyPOS system is self-cleaning, which means that it eliminates the need for QSRs to clean their printers on a regular basis. This helps to maximise printer uptime and reduces the chances of errors. StickyPOS labels are linerless, which means that they produce zero waste. In addition, StickyPOS labels do not contain BPA, a chemical commonly used in thermal papers.

Implementing StickyPOS into your QSR

If you’re looking for a way to improve the efficiency of your QSR, StickyPOS may be the perfect solution. To learn more about StickyPOS and how to implement it into your QSR, visit their website or contact their team today.